Diego Reynoso

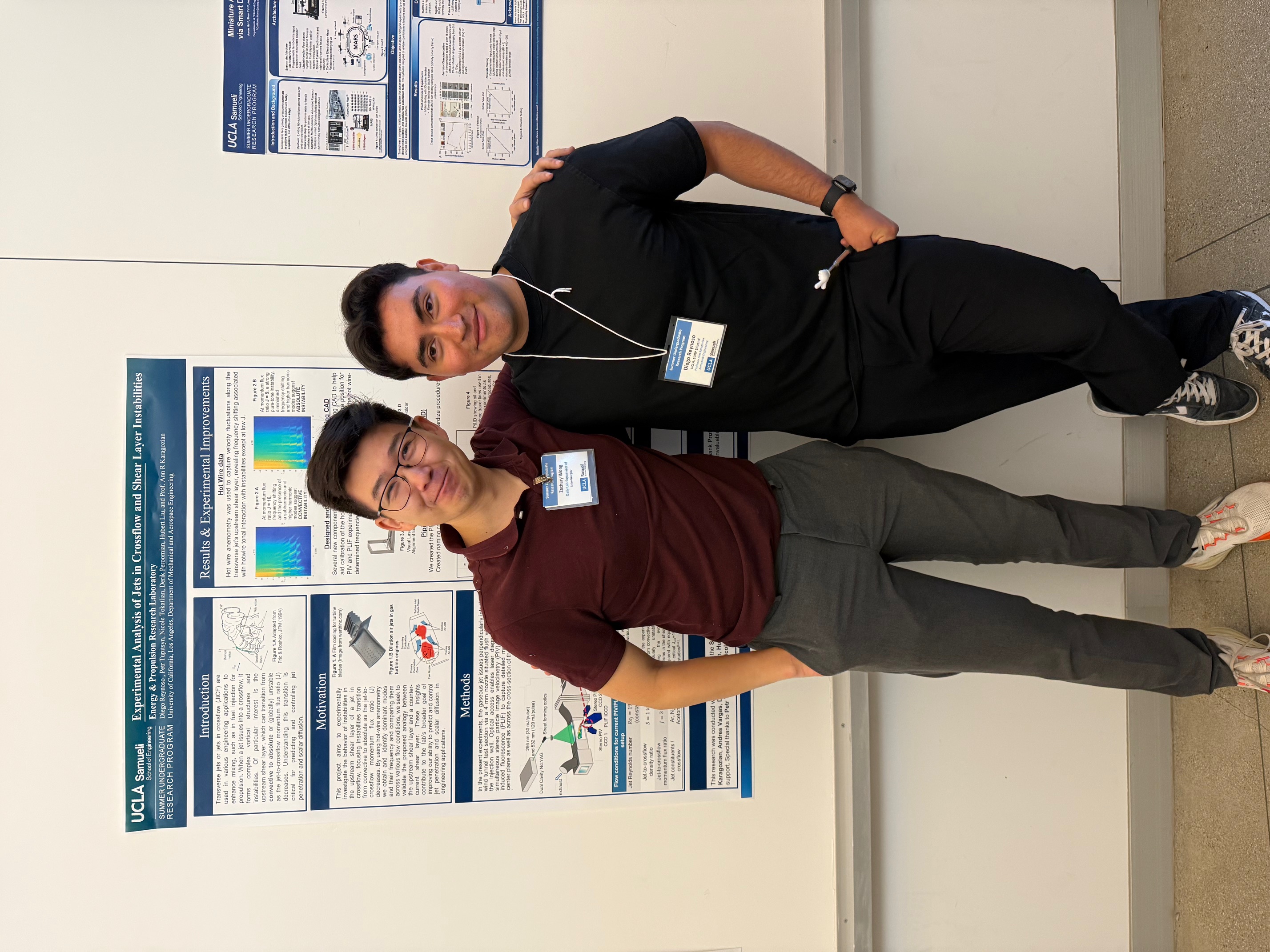

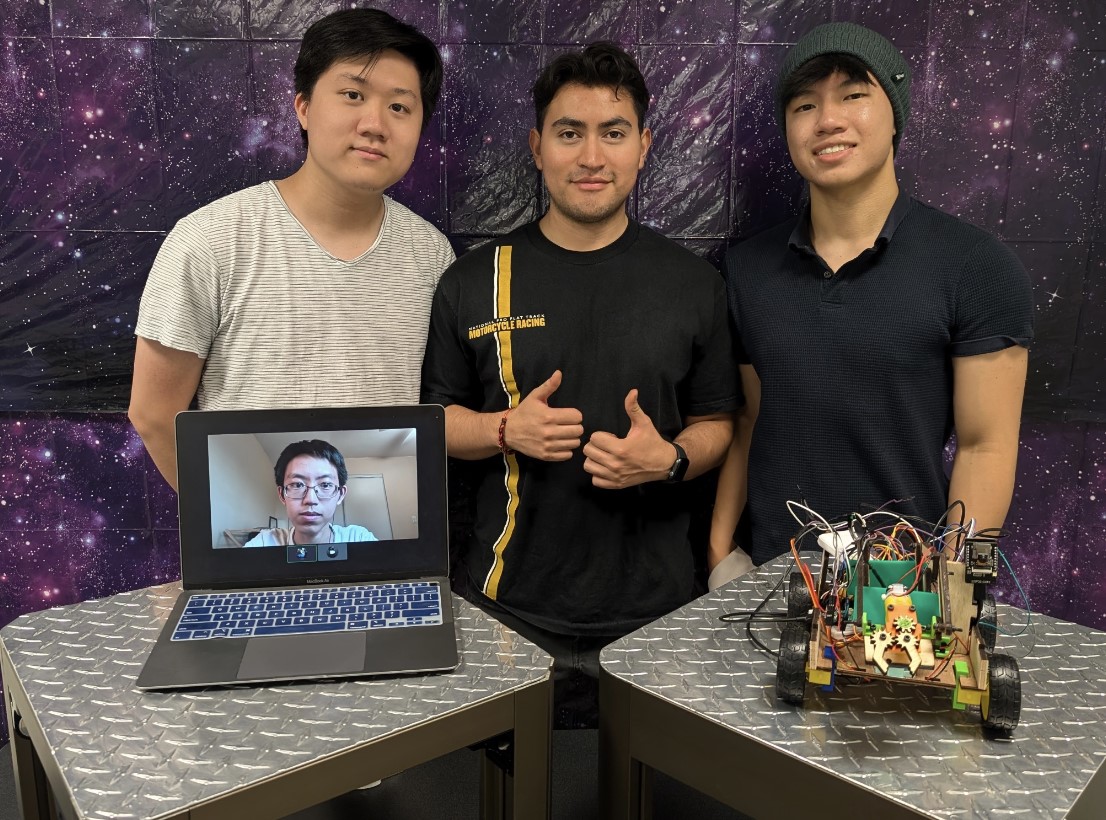

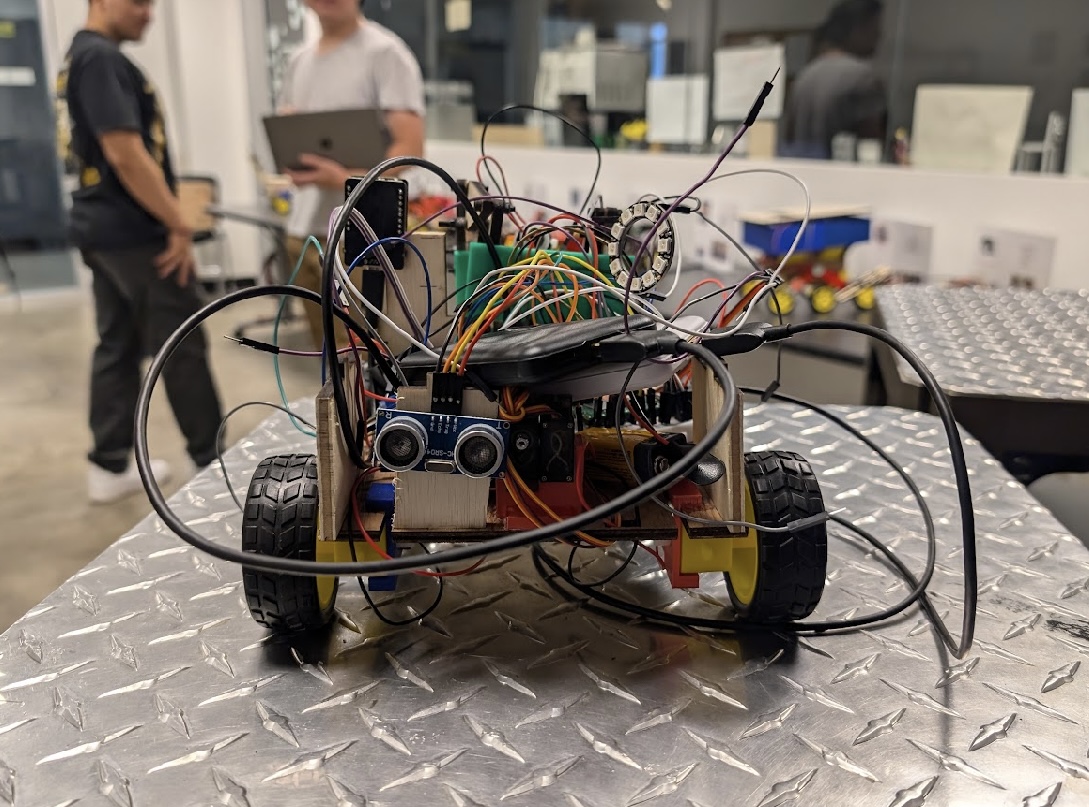

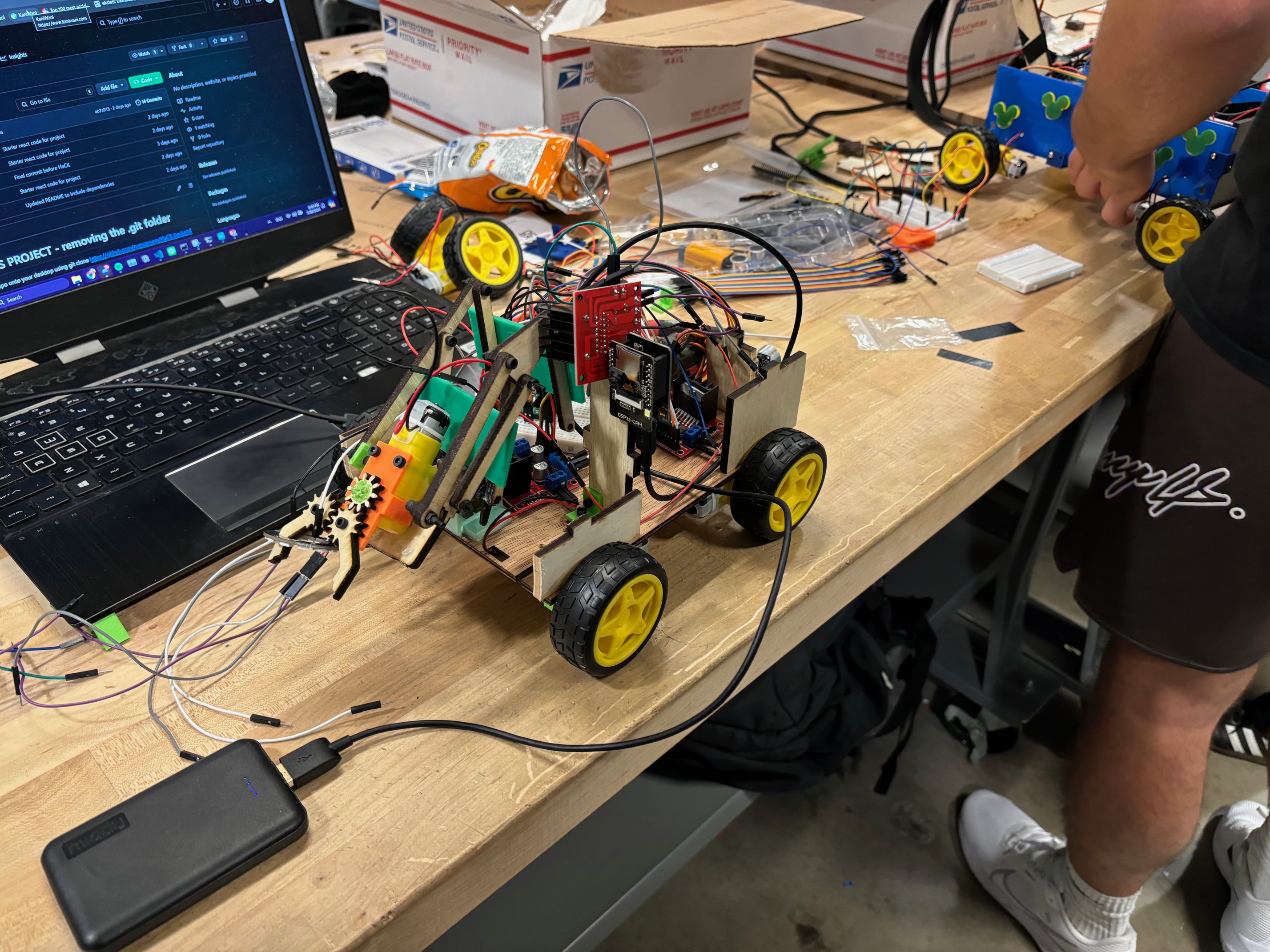

I’m an Aerospace Engineering student at UCLA with a passion for solving real-world problems through hands-on design, testing, and iteration. My interests center on fluid mechanics, as well as mechanical and thermal systems, which are reflected in much of my academic and project work. I bring strong leadership experience from previous roles and thrive in collaborative environments where teams tackle difficult engineering challenges together. I am currently engaged in aerospace research and continue to grow my skills through both academic work and independent projects in clubs and engineering organizations.